Dollar Fulfillment’s White-Glove Approach to Fulfillment

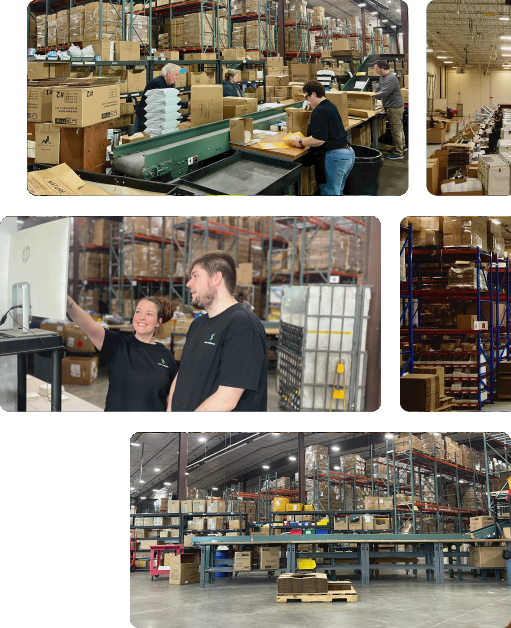

In the realm of logistics, efficiency and reliability are the cornerstones of success. Third-party logistics (3PL) providers like Dollar Fulfillment play a pivotal role in

With a 99.8% accuracy rate and a network that reaches 99% of the US population within 48 hours sets us apart as your premier fulfillment partner. Our technology, uncompromising care, and scalable solutions deliver a premium service with incredible value, at no sacrifice to quality.

Fast, easy, turn-key product fulfillment

Our low-cost, worry-free, worldwide fulfillment keeps your customers happy and your bottom line growing. No return processing, hidden fees, delays, or paying unneeded services. Grow your bottom line and your business while reducing your shipping costs and improving customer satisfaction.

Our concentrated focus on accuracy and efficiency ensures that every order counts to elevate your profits and propel your business to new heights.

Our business model is specifically tailored to being an affordable fulfillment company offering a premium service, focused on the shipping needs of high-volume, low-SKU, direct-to-consumer brands.

There’s no catch. By focusing on this one type of client, we streamline our process. Time is money—so it’s treated as such. We prioritize value, not cost, and with us, that’s exactly what you’ll get.

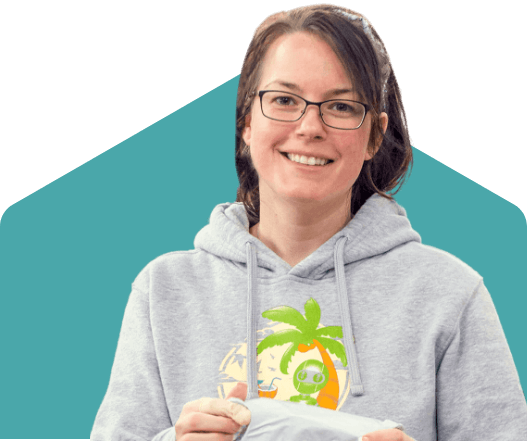

When you choose us to handle your dollar, you get direct access to the person in charge of printing your labels and overseeing your specific packaging requirements on the warehouse floor. Connect with your personal packer within minutes during business hours for prompt assistance and customized white-glove care and quality.

We are your partner in the hyper-growth fulfillment space. Your value brings us value. When you succeed, we succeed. Our white-glove approach speaks to our genuine and superior care—the cornerstone of our company. We value you and your business, so we make sure you value ours.

Daily inventory management.

Inventory levels are updated daily—delivering information in real-time to help you manage cash flow, control expenses, and increase your margins.

Easy and seamless cart integration.

We integrate with nearly all eCommerce platforms via API in less than 2 minutes and ship worldwide, reaching 99% of the population within 48 hours. Time is money—so we don’t waste it.

No hidden fees. Superior service.

We offer fully transparent pricing and easy-to-understand billing, as well as the white-glove service you and your customers deserve.

"Jason is not only a great connector of those who can help but he himself is solid, reliable, focused support for business. You'll be amazed how much better you'll feel having him on your team. He flawlessly fulfilled hundreds of requests. I highly recommend him!

"Jason is not only a great connector of those who can help but he himself is solid, reliable, focused support for business. You'll be amazed how much better you'll feel having him on your team. He flawlessly fulfilled hundreds of requests. I highly recommend him!

"Jason was enormously helpful with our flash-drive fulfillment for our recent summit. He was able to offer us better pricing, better terms, and, ultimately, fantastic service. He was extremely available and responsive throughout the whole process, and we will definitely be using him again."

"Jason was enormously helpful with our flash-drive fulfillment for our recent summit. He was able to offer us better pricing, better terms, and, ultimately, fantastic service. He was extremely available and responsive throughout the whole process, and we will definitely be using him again."

"Jason and his company provide fast, reliable, and affordable fulfillment services. I am very pleased with the service I received and would recommend him to anyone looking for product fulfillment."

"Jason and his company provide fast, reliable, and affordable fulfillment services. I am very pleased with the service I received and would recommend him to anyone looking for product fulfillment."

“Jason has been a godsend to my business as his flash drive and fulfillment services boosted my online event revenue by over $150K. Fast turnaround, on-time delivery, and very easy to work with. Highly recommended!”

“Jason has been a godsend to my business as his flash drive and fulfillment services boosted my online event revenue by over $150K. Fast turnaround, on-time delivery, and very easy to work with. Highly recommended!”

"Jason is not only a great connector of those who can help but he himself is solid, reliable, focused support for business. You'll be amazed how much better you'll feel having him on your team. He flawlessly fulfilled hundreds of requests. I highly recommend him!

"Jason is not only a great connector of those who can help but he himself is solid, reliable, focused support for business. You'll be amazed how much better you'll feel having him on your team. He flawlessly fulfilled hundreds of requests. I highly recommend him!

"Jason was enormously helpful with our flash-drive fulfillment for our recent summit. He was able to offer us better pricing, better terms, and, ultimately, fantastic service. He was extremely available and responsive throughout the whole process, and we will definitely be using him again."

"Jason was enormously helpful with our flash-drive fulfillment for our recent summit. He was able to offer us better pricing, better terms, and, ultimately, fantastic service. He was extremely available and responsive throughout the whole process, and we will definitely be using him again."

"Jason and his company provide fast, reliable, and affordable fulfillment services. I am very pleased with the service I received and would recommend him to anyone looking for product fulfillment."

"Jason and his company provide fast, reliable, and affordable fulfillment services. I am very pleased with the service I received and would recommend him to anyone looking for product fulfillment."

“Jason has been a godsend to my business as his flash drive and fulfillment services boosted my online event revenue by over $150K. Fast turnaround, on-time delivery, and very easy to work with with. Highly recommended!”

“Jason has been a godsend to my business as his flash drive and fulfillment services boosted my online event revenue by over $150K. Fast turnaround, on-time delivery, and very easy to work with with. Highly recommended!”

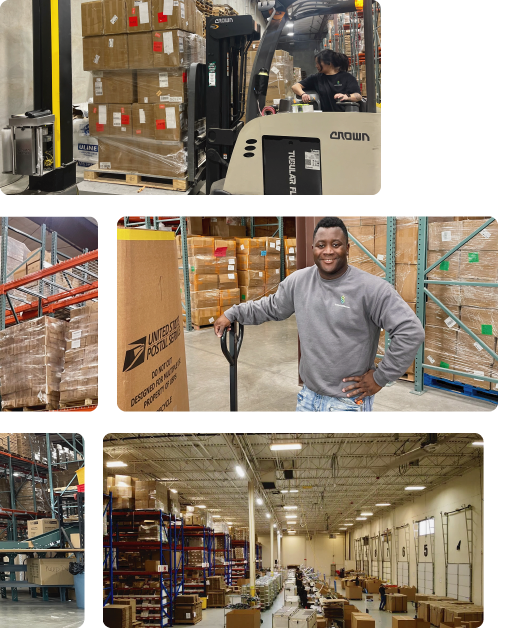

Other fulfillment companies treat you and your customers like numbers on a spreadsheet. We treat you like family. Other fulfillment companies treat their employees like replaceable robots. We treat our employees like family.

People love coming to work here each day. You might not imagine a warehouse floor could be a warm, friendly, happy place—but ours is. We take care of our employees, and they take care of us, they take care of you, and they take care of your customers.

“Proin ex ipsum, facilisis id tincidunt sed, vulputate in lacus. Donec pharetra faucibus leo, vitae vestibulum leo scelerisque eu. Nam enim dolor, porta at ex ut, eleifend tristique metus. Integer sit amet auctor ligula, vel dictum orci. Nam feugiat interdum nisl.”

“Proin ex ipsum, facilisis id tincidunt sed, vulputate in lacus. Donec pharetra faucibus leo, vitae vestibulum leo scelerisque eu. Nam enim dolor, porta at ex ut, eleifend tristique metus. Integer sit amet auctor ligula, vel dictum orci. Nam feugiat interdum nisl.”

“Proin ex ipsum, facilisis id tincidunt sed, vulputate in lacus. Donec pharetra faucibus leo, vitae vestibulum leo scelerisque eu. Nam enim dolor, porta at ex ut, eleifend tristique metus. Integer sit amet auctor ligula, vel dictum orci. Nam feugiat interdum nisl.”

In the realm of logistics, efficiency and reliability are the cornerstones of success. Third-party logistics (3PL) providers like Dollar Fulfillment play a pivotal role in

In the competitive landscape of product fulfillment, where efficiency and reliability are paramount, the choice of a fulfillment center can significantly impact customer service. While

Welcome to Dollar Fulfillment, where we’re not just a logistics provider – we’re your strategic partner in success. We pride ourselves on going beyond the

OUR SERVICES